Understanding the Importance of Vacuum Roller Cleaning Systems in Papermaking Equipment

Published on:

2025-01-25 12:20

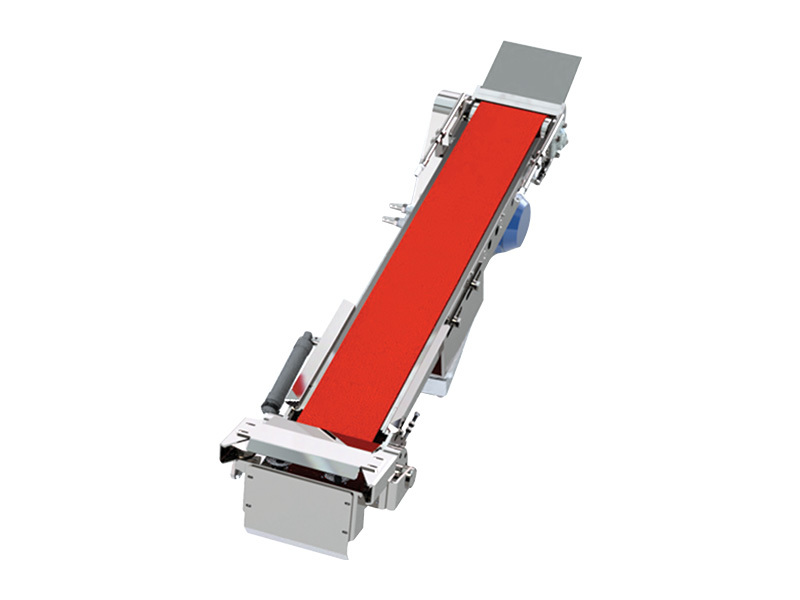

In the papermaking process, the vacuum roller is an integral component that helps remove excess water from the pulp, contributing to the formation of a consistent paper sheet. However, as with any manufacturing equipment, these rollers can accumulate debris, fibers, and contaminants over time. This buildup not only affects the quality of the final product but can also lead to operational inefficiencies and increased maintenance costs.

The implementation of a vacuum roller cleaning system is essential for addressing these challenges. These systems utilize suction mechanisms to eliminate unwanted residues from the roller surface, ensuring optimal performance. By regularly cleaning the vacuum rollers, manufacturers can maintain a uniform flow of pulp, which is crucial for producing high-quality paper. The benefits of such cleaning systems extend beyond cleanliness; they also enhance the longevity of the equipment, reducing the frequency of repairs and replacements.

One of the primary advantages of a vacuum roller cleaning system is its ability to improve the overall efficiency of the papermaking process. Clean rollers facilitate better water removal, which leads to faster drying times and increased production rates. This efficiency translates to cost savings, as manufacturers can produce more paper in less time without compromising quality. Moreover, by minimizing downtime associated with cleaning and maintenance, companies can maximize their operational output.

In addition to efficiency, a vacuum roller cleaning system plays a vital role in ensuring product quality. Contaminants on the rollers can lead to imperfections in the paper, such as spots, streaks, or uneven textures. By maintaining clean rollers, manufacturers can achieve a smoother and more uniform finished product, meeting the high standards expected in the industry. This attention to detail not only satisfies customer expectations but also enhances the brand's reputation.

Moreover, the adoption of advanced vacuum roller cleaning technologies can lead to environmental benefits. Many modern systems are designed to minimize water usage and reduce waste, aligning with the industry’s shift towards sustainable practices. By implementing these systems, manufacturers can contribute to eco-friendly production methods while maintaining high operational standards.

In conclusion, vacuum roller cleaning systems are a critical component of papermaking equipment that significantly impacts efficiency, product quality, and sustainability. By investing in these cleaning systems, manufacturers can ensure their equipment operates at peak performance, ultimately leading to enhanced production outcomes and customer satisfaction.

The implementation of a vacuum roller cleaning system is essential for addressing these challenges. These systems utilize suction mechanisms to eliminate unwanted residues from the roller surface, ensuring optimal performance. By regularly cleaning the vacuum rollers, manufacturers can maintain a uniform flow of pulp, which is crucial for producing high-quality paper. The benefits of such cleaning systems extend beyond cleanliness; they also enhance the longevity of the equipment, reducing the frequency of repairs and replacements.

One of the primary advantages of a vacuum roller cleaning system is its ability to improve the overall efficiency of the papermaking process. Clean rollers facilitate better water removal, which leads to faster drying times and increased production rates. This efficiency translates to cost savings, as manufacturers can produce more paper in less time without compromising quality. Moreover, by minimizing downtime associated with cleaning and maintenance, companies can maximize their operational output.

In addition to efficiency, a vacuum roller cleaning system plays a vital role in ensuring product quality. Contaminants on the rollers can lead to imperfections in the paper, such as spots, streaks, or uneven textures. By maintaining clean rollers, manufacturers can achieve a smoother and more uniform finished product, meeting the high standards expected in the industry. This attention to detail not only satisfies customer expectations but also enhances the brand's reputation.

Moreover, the adoption of advanced vacuum roller cleaning technologies can lead to environmental benefits. Many modern systems are designed to minimize water usage and reduce waste, aligning with the industry’s shift towards sustainable practices. By implementing these systems, manufacturers can contribute to eco-friendly production methods while maintaining high operational standards.

In conclusion, vacuum roller cleaning systems are a critical component of papermaking equipment that significantly impacts efficiency, product quality, and sustainability. By investing in these cleaning systems, manufacturers can ensure their equipment operates at peak performance, ultimately leading to enhanced production outcomes and customer satisfaction.

Latest News