Product Center

Office Telephone

overseas.admin@meixin-paper.com

Factory Address

Building 14&15, International Laser Industrial Park, High Tech District, Jinan, Shandong

Water Needle Tail Cutter for Wet Section

Specification thickness: color steel products 0.08mm- 0.8mm; color aluminum products are 0.15mm-1.5mm

Keywords:

Water Needle Tail Cutter for Wet Section

Series:

Product Details

Automatic Water Needle Tail Cutter for We't Section

Paper edge cutting is trim and stable

Tail threading process is safe and reliable

Electric Automatic Positioning

Safe & Reliable Operation

Smooth & Stable Paper Threading

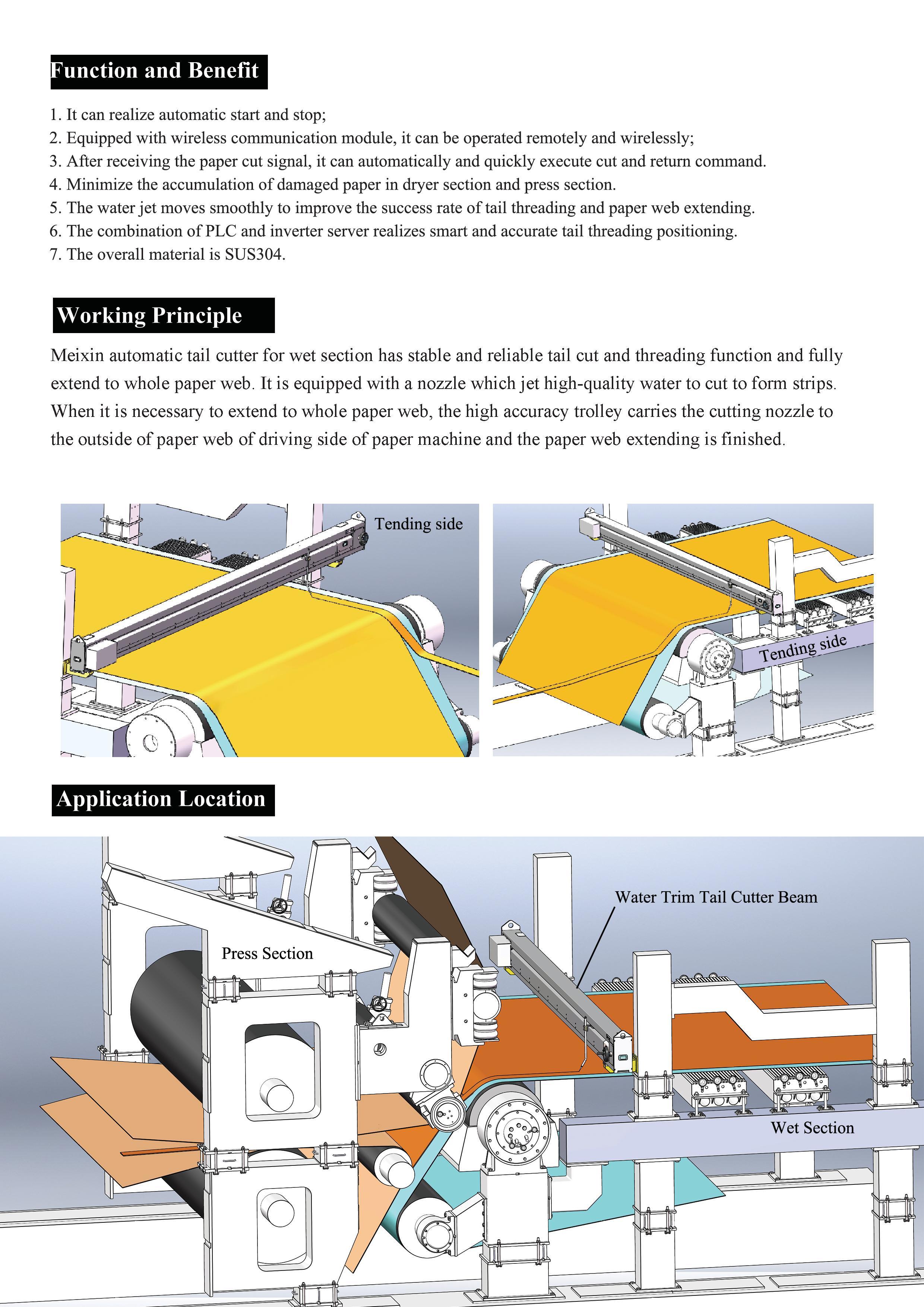

Function and Benefits

1. The pneumatic motor drives the blade to cut paper, and its Max. speed is 9000r/min;

2. Edge cutting is neat without flying paper scraps;

3. Electric automatic positioning, convenient operation, time-saving and labor-saving;

4. It is equipped with a mobile hand wheel which can be moved horizontally manually or electrically;

5. The trolley moves stably, and the paper tail and cutting are stable;

6. The paper stabilizing wind plate is configured to ensure the paper web is stable without shake and maximize the success rate of paper threading.

Work Principle

The automatic tail cutter for dry section of Meixin has the function of cutting the paper guiding strip and extending paper web. It is equipped with an imported high speed pneumatic motor which will be used to drive the special paper cutting blade. The high speed rotating blade cuts the paper to strips. When it is necessary to extend the full paper web, high precision mobile car carries the rotating blade and moves it to the paper machine At the same time, the paper web extending is finished.

Previous Article

Next Article

Previous Article

Next Article