Product Center

Office Telephone

overseas.admin@meixin-paper.com

Factory Address

Building 14&15, International Laser Industrial Park, High Tech District, Jinan, Shandong

Ropeless Automatic Tail Threading System

Specification thickness: color steel products 0.08mm- 0.8mm; color aluminum products are 0.15mm-1.5mm

Keywords:

Ropeless Automatic Tail Threading System

Product Details

Ropeless Automatic Tail Threading System

Shorten tail threading time

Increase tail threading speed

Fast and Efficient Automatic Tail Threading System

Increase Tail Threading Efficiency

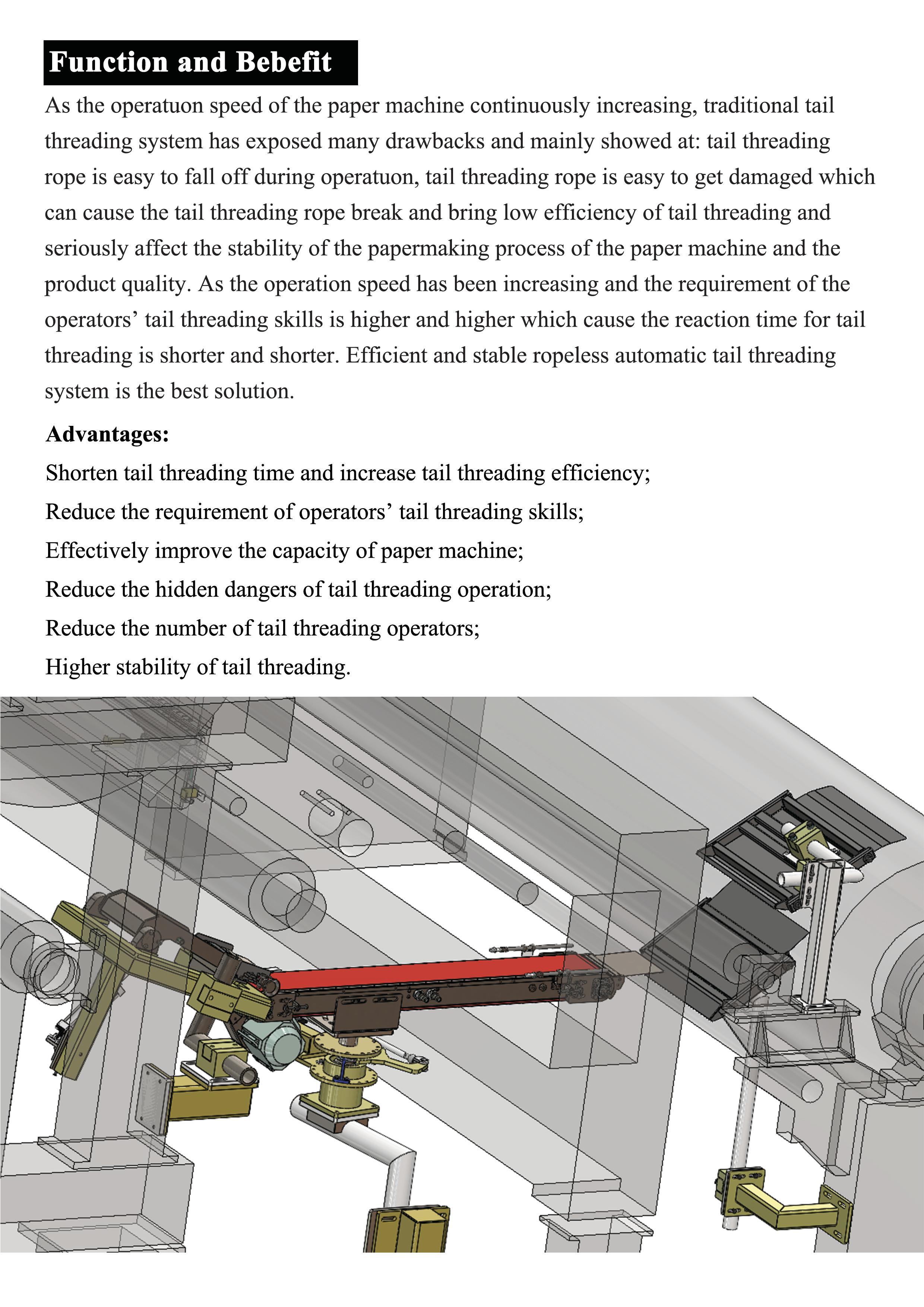

Functions and Bebefits

As the running speed of paper machine continuously increasing, traditional tail threading system has exposed many drawbacks and mainly showed at: tail threading rope is easy to fall off during running, tail threading rope is easy to get damaged which can cause the tail threading rope break and so causing the tail threading efficiency is low and seriously affect the stability of the paper making process of the paper machine and the product quality. As the running speed has been increasing and the requirement of the operators’tail threading skills is higher and higher which cause the reaction time for tail threading is shorter and shorter. Efficient and stable ropeless automatic tail threading system is the best solution.

Advantages:

1. Shorten tail threading time and increase tail threading efficiency;

2. Reduce the requirement of operators’tail threading skills;

3. Effectively improve the capacity of paper machine;

4. Reduce the hidden dangers of tail threading operation safety;

5. Reduce the number of tail threading operators;

6. Higher stability of tail threading.

Previous Article

Next Article

Previous Article

Next Article