Product Center

Office Telephone

overseas.admin@meixin-paper.com

Factory Address

Building 14&15, International Laser Industrial Park, High Tech District, Jinan, Shandong

Edge Trim For Forming Fabric

Specification thickness: color steel products 0.08mm- 0.8mm; color aluminum products are 0.15mm-1.5mm

Keywords:

Edge Trim For Forming Fabric

Series:

Product Details

Edge Trim For Forming Fabric

Work principle

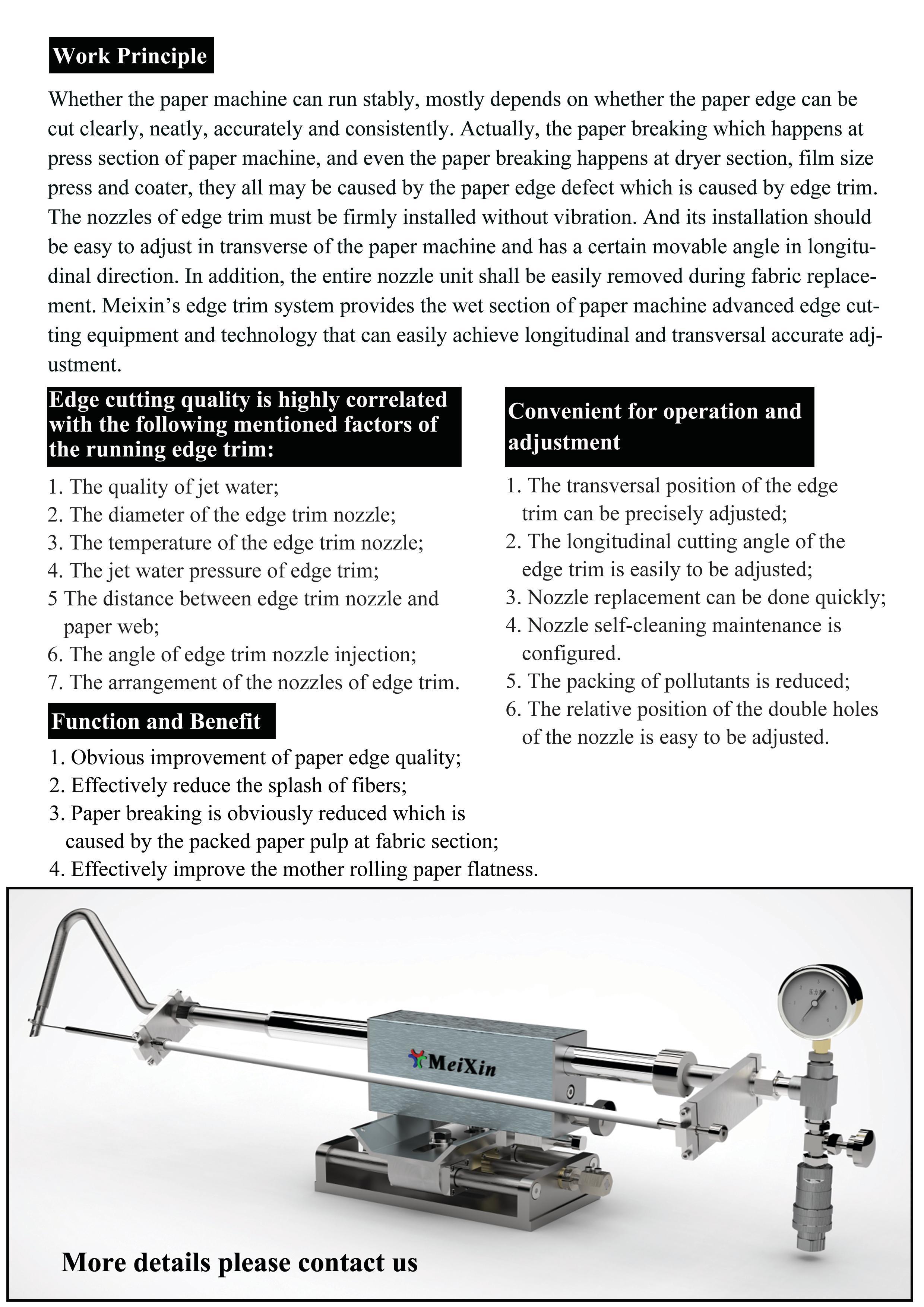

Whether the paper machine can run stably, mostly depends on whether the paper edge can be cut clearly, neatly, accurately and consistently. Actually, the paper breaking which happens at press section of paper machine, and even the paper breaking happens at dryer section, film size press and coater, they all may be caused by the paper edge defect which is caused by edge trim.The nozzles of edge trim must be firmly installed without vibration. And its installation should be easy to adjust in transverse of the paper machine and has a certain movable angle in longitudinal direction. In addition, the entire nozzle unit shall be easily removed during fabric replacement. Meixin's edge trim system provides the wet section of paper machine advanced edge cutting equipment and technology that can easily achieve longitudinal and transversal accurate adjustment.

The quality of edge cutting is highly correlated with the following factors

1. The quality of jet water;

2. The diameter of the edge trim nozzle;

3. The temperature of the edge trim nozzle;

4. The jet water pressure of edge trim;

5. The distance between edge trim nozzle and paper web;

6. The angle of edge trim nozzle injection;

7. The arrangement of the nozzles of edge trim.

Convenient for operation and adjustment

1. The transversal position of the edge trim can be precisely adjusted;

2. The longitudinal cutting angle of the edge trim is easily to be adjusted;

3. Nozzle replacement can be done quickly;

4. Nozzle self-cleaning maintenance is configured;

5. The packing of pollutants is reduced;

6. The relative position of the double holes of the nozzle is easy to be adjusted.

Function and Benefit

1. Obvious improvement of paper edge quality;

2. Effectively reduce the splash of fibers;

3. Paper breaking is obviously reduced which is caused by the packed paper pulp at fabric section;

4. Effectively improve the mother rolling paper flatness.

Previous Article

Next Article

Previous Article

Next Article