Revolutionizing Manufacturing with the Ropeless Automatic Tail Threading System

Published on:

2025-02-24 11:20

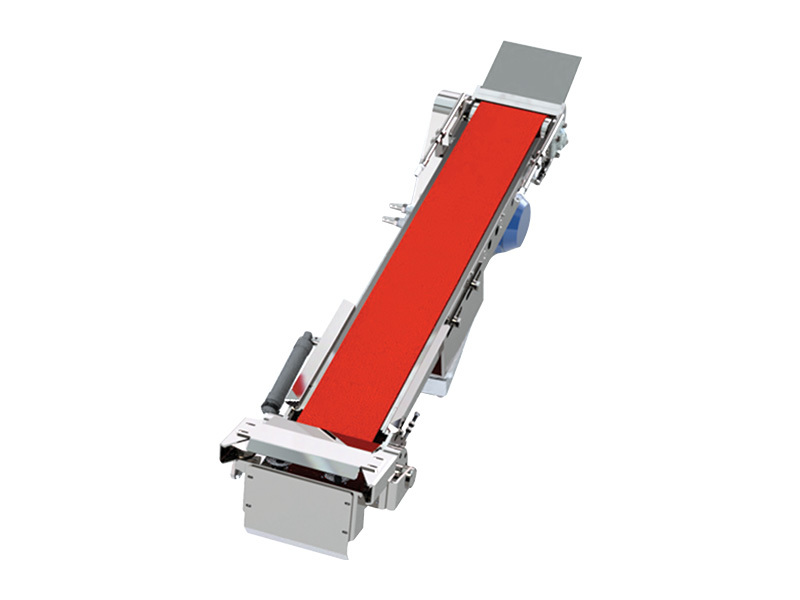

In the rapidly evolving landscape of manufacturing technology, efficiency and precision are paramount. One of the most exciting advancements is the Ropeless Automatic Tail Threading System, designed to streamline the threading process in various manufacturing applications. This system stands out for its ability to eliminate the need for traditional threading ropes, thus simplifying operations and reducing potential points of failure.

The Ropeless Automatic Tail Threading System operates using advanced mechanics that allow for seamless and automatic threading of materials. This innovation not only increases operational speed but also minimizes manual intervention, which can often lead to inconsistencies and errors. By automating this critical function, manufacturers can achieve higher levels of productivity, allowing for more focus on quality control and product development.

Another significant advantage of this system is its adaptability across various machinery types. It's engineered to accommodate different materials and thread sizes, making it versatile for numerous manufacturing sectors. This flexibility means that businesses can implement the Ropeless Automatic Tail Threading System without needing extensive modifications to their existing equipment, leading to a more efficient transition and quicker return on investment.

The Ropeless Automatic Tail Threading System also contributes to improved safety within the manufacturing environment. With fewer manual processes involved in threading, the risk of workplace accidents related to these operations is significantly reduced. This focus on safety, combined with increased efficiency, makes this system an attractive option for companies looking to enhance both productivity and workplace safety.

Furthermore, the Ropeless Automatic Tail Threading System is designed with maintenance in mind. Its robust construction and fewer moving parts mean that it requires less frequent servicing compared to traditional systems. This durability not only extends the lifespan of the equipment but also reduces downtime, ensuring that production schedules are met without interruption.

In conclusion, the Ropeless Automatic Tail Threading System is a pivotal advancement in manufacturing technology. By automating the threading process, it enhances efficiency, safety, and reliability in production lines. Manufacturers looking to improve their operational capabilities should consider the integration of this innovative system into their processes. Embracing such technology can lead to significant improvements in both productivity and product quality, ultimately contributing to the success of a manufacturing business in a competitive marketplace.

The Ropeless Automatic Tail Threading System operates using advanced mechanics that allow for seamless and automatic threading of materials. This innovation not only increases operational speed but also minimizes manual intervention, which can often lead to inconsistencies and errors. By automating this critical function, manufacturers can achieve higher levels of productivity, allowing for more focus on quality control and product development.

Another significant advantage of this system is its adaptability across various machinery types. It's engineered to accommodate different materials and thread sizes, making it versatile for numerous manufacturing sectors. This flexibility means that businesses can implement the Ropeless Automatic Tail Threading System without needing extensive modifications to their existing equipment, leading to a more efficient transition and quicker return on investment.

The Ropeless Automatic Tail Threading System also contributes to improved safety within the manufacturing environment. With fewer manual processes involved in threading, the risk of workplace accidents related to these operations is significantly reduced. This focus on safety, combined with increased efficiency, makes this system an attractive option for companies looking to enhance both productivity and workplace safety.

Furthermore, the Ropeless Automatic Tail Threading System is designed with maintenance in mind. Its robust construction and fewer moving parts mean that it requires less frequent servicing compared to traditional systems. This durability not only extends the lifespan of the equipment but also reduces downtime, ensuring that production schedules are met without interruption.

In conclusion, the Ropeless Automatic Tail Threading System is a pivotal advancement in manufacturing technology. By automating the threading process, it enhances efficiency, safety, and reliability in production lines. Manufacturers looking to improve their operational capabilities should consider the integration of this innovative system into their processes. Embracing such technology can lead to significant improvements in both productivity and product quality, ultimately contributing to the success of a manufacturing business in a competitive marketplace.

Latest News