Revolutionizing Efficiency: The Importance of Vacuum Roller Cleaning Systems in Papermaking Equipment

Published on:

2025-03-06 11:40

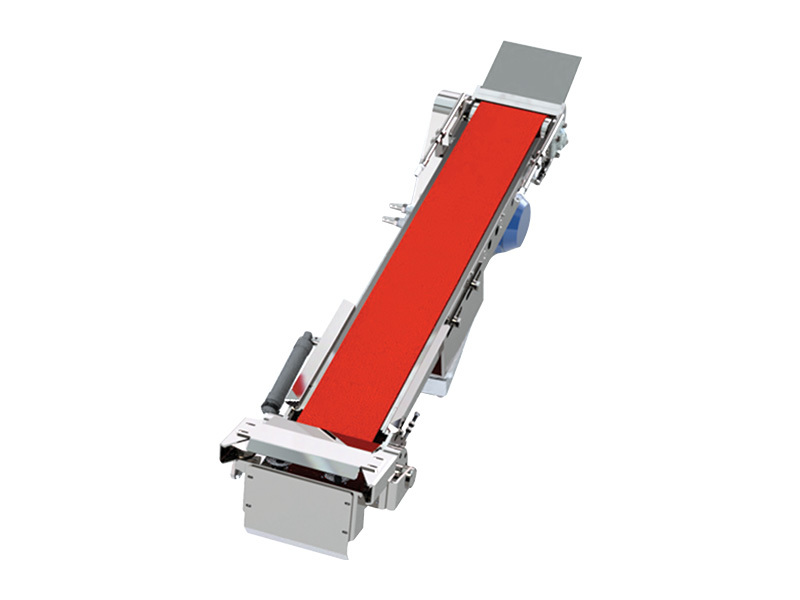

In the realm of papermaking, the cleanliness of equipment plays a crucial role in ensuring product quality, operational efficiency, and equipment longevity. One essential component that contributes to this cleanliness is the vacuum roller cleaning system. This system is designed to remove debris, fibers, and contaminants from the rollers used in papermaking, thus minimizing downtime and enhancing the overall manufacturing process.

The vacuum roller cleaning system operates by using suction to gather unwanted materials from the rollers' surface. This not only prevents the buildup of contaminants that can affect the quality of the paper produced but also reduces the frequency of manual cleaning, which can be labor-intensive and time-consuming. By integrating such a system, manufacturers can achieve a more streamlined operation, ultimately leading to higher productivity and lower operational costs.

One of the key advantages of implementing a vacuum roller cleaning system is its role in improving product quality. Inconsistent roller surfaces can lead to defects in the paper, such as uneven texture and color inconsistencies. By ensuring that rollers are consistently clean, manufacturers can produce higher-quality products that meet industry standards and customer expectations. This is particularly critical in a competitive market where product quality can differentiate a manufacturer from its competitors.

Another important aspect is the system's contribution to equipment maintenance. Dirt and debris can cause wear and tear on rollers, leading to premature failure and expensive repairs. A vacuum roller cleaning system helps to prolong the lifespan of these components by keeping them in optimal condition. This preventive maintenance approach not only saves costs in the long run but also enhances the overall reliability of the papermaking equipment.

Moreover, the implementation of a vacuum roller cleaning system aligns with sustainability goals. By reducing waste generated during the cleaning process and minimizing the need for chemical cleaners, manufacturers can significantly lower their environmental impact. This is increasingly important as industries move toward more sustainable practices and seek to comply with environmental regulations.

In conclusion, a vacuum roller cleaning system is a critical investment for any papermaking equipment manufacturer looking to enhance efficiency, improve product quality, and reduce operational costs. By adopting such systems, companies can ensure their machinery operates at peak performance while also contributing to sustainability efforts. As the industry continues to evolve, integrating advanced cleaning solutions like vacuum roller systems will be essential for maintaining a competitive edge in the market.

The vacuum roller cleaning system operates by using suction to gather unwanted materials from the rollers' surface. This not only prevents the buildup of contaminants that can affect the quality of the paper produced but also reduces the frequency of manual cleaning, which can be labor-intensive and time-consuming. By integrating such a system, manufacturers can achieve a more streamlined operation, ultimately leading to higher productivity and lower operational costs.

One of the key advantages of implementing a vacuum roller cleaning system is its role in improving product quality. Inconsistent roller surfaces can lead to defects in the paper, such as uneven texture and color inconsistencies. By ensuring that rollers are consistently clean, manufacturers can produce higher-quality products that meet industry standards and customer expectations. This is particularly critical in a competitive market where product quality can differentiate a manufacturer from its competitors.

Another important aspect is the system's contribution to equipment maintenance. Dirt and debris can cause wear and tear on rollers, leading to premature failure and expensive repairs. A vacuum roller cleaning system helps to prolong the lifespan of these components by keeping them in optimal condition. This preventive maintenance approach not only saves costs in the long run but also enhances the overall reliability of the papermaking equipment.

Moreover, the implementation of a vacuum roller cleaning system aligns with sustainability goals. By reducing waste generated during the cleaning process and minimizing the need for chemical cleaners, manufacturers can significantly lower their environmental impact. This is increasingly important as industries move toward more sustainable practices and seek to comply with environmental regulations.

In conclusion, a vacuum roller cleaning system is a critical investment for any papermaking equipment manufacturer looking to enhance efficiency, improve product quality, and reduce operational costs. By adopting such systems, companies can ensure their machinery operates at peak performance while also contributing to sustainability efforts. As the industry continues to evolve, integrating advanced cleaning solutions like vacuum roller systems will be essential for maintaining a competitive edge in the market.

Latest News