Sustainable Solutions: Uncovering the Environmental Benefits of Vacuum Roll Systems in Production

Published on:

2025-06-29 10:20

Sustainable Solutions: Uncovering the Environmental Benefits of Vacuum Roll Systems in Production

Table of Contents

- Introduction to Vacuum Roll Systems

- What are Vacuum Roll Systems?

- How Vacuum Roll Systems Work

- Environmental Benefits of Vacuum Roll Systems

- Economic Advantages of Vacuum Roll Systems

- Case Studies: Successful Implementation

- Future Trends in Vacuum Roll Systems

- Conclusion

- FAQs

Introduction to Vacuum Roll Systems

In today's rapidly evolving industrial landscape, sustainability has moved from a buzzword to a necessity. As manufacturing industries seek to minimize their environmental impact, **vacuum roll systems** have emerged as a beacon of innovation. These systems not only enhance production efficiency but also pave the way for greener manufacturing practices. By integrating vacuum technology into production lines, companies can significantly reduce their carbon footprint while optimizing resource usage.

What are Vacuum Roll Systems?

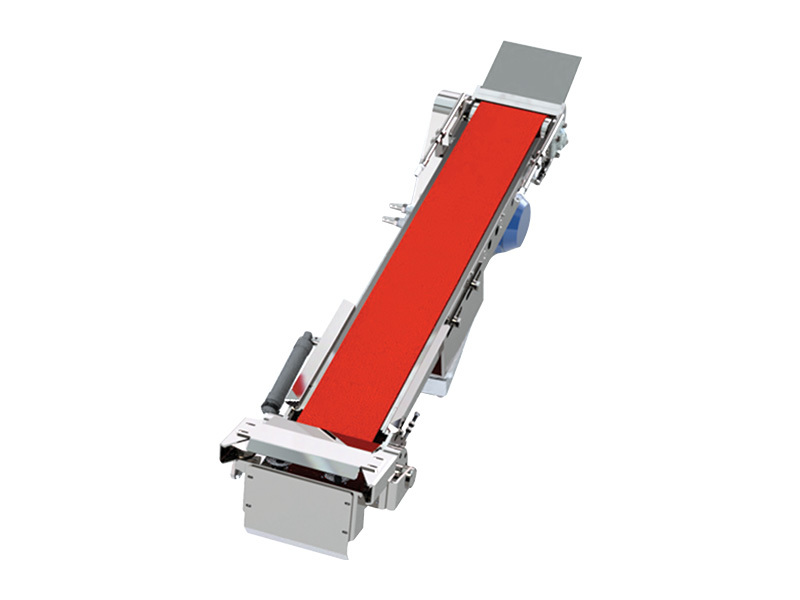

Vacuum roll systems are advanced conveyor mechanisms that utilize vacuum pressure to transport materials during the manufacturing process. Unlike traditional conveyor belts, which rely on mechanical motion to move products, vacuum systems leverage suction to securely hold and transport items, minimizing movement and potential damage. These systems are widely used in various sectors, including packaging, textiles, and automotive manufacturing, due to their versatility and efficiency.

How Vacuum Roll Systems Work

At the heart of vacuum roll systems is a series of rollers equipped with suction capabilities. When materials are placed on the conveyor, a vacuum is created beneath them, holding the items firmly in place. This method allows for smooth transitions between production stages without the risk of dropping or misaligning products. The suction pressure can be adjusted according to the weight and type of material being transported, making this system adaptable to diverse manufacturing needs.

Environmental Benefits of Vacuum Roll Systems

The integration of vacuum roll systems in production lines offers a multitude of environmental benefits. Let's delve into four key advantages that make these systems an eco-friendly choice.

1. Energy Efficiency

Vacuum roll systems are designed to consume less energy compared to traditional mechanical conveyor systems. By minimizing friction and mechanical wear, these systems operate more efficiently, leading to lower energy costs. Additionally, many vacuum systems utilize variable speed drives, allowing manufacturers to adjust the speed according to production needs, further optimizing energy consumption.

2. Waste Reduction

In manufacturing, waste not only refers to excess materials but also to inefficiencies in the production process. Vacuum roll systems can significantly reduce material waste by ensuring precise handling and transport. The secure grip provided by vacuum technology decreases the likelihood of damage during transit, thus minimizing product loss. Moreover, the ability to transport delicate items reduces the need for additional packaging materials, contributing to less environmental waste.

3. Resource Conservation

Sustainability is fundamentally about resource conservation, and vacuum roll systems excel in this area. By optimizing material flow and reducing waste, manufacturers can make the most out of their raw materials. This efficient use of resources not only contributes to environmental protection but also enhances the overall sustainability of the production process.

4. Recyclability of Materials

Many industries are now focusing on the recyclability of materials used in production. Vacuum roll systems support this trend by facilitating the handling of recyclable materials more effectively. By securely transporting recyclable items to the appropriate processing stations, these systems help ensure that materials are reused and repurposed, thus contributing to a circular economy.

Economic Advantages of Vacuum Roll Systems

While the environmental benefits of vacuum roll systems are significant, the economic advantages should not be overlooked. Companies that adopt vacuum technology often experience reduced operational costs due to lower energy consumption and decreased material waste. These savings can directly impact the bottom line, making such systems an attractive investment for manufacturers aiming for both profitability and sustainability.

Case Studies: Successful Implementation

Several companies across diverse industries have successfully implemented vacuum roll systems, showcasing their effectiveness in enhancing sustainability. For instance, a leading packaging company reported a **30% reduction in energy costs** after transitioning to a vacuum system, while a textile manufacturer achieved a remarkable **25% decrease in material waste**.

These case studies emphasize that the shift towards vacuum technology is not merely about adhering to environmental regulations; it is a strategic move that can yield substantial benefits in efficiency and cost savings.

Future Trends in Vacuum Roll Systems

As technology continues to advance, the future of vacuum roll systems looks promising. Ongoing research and development aim to enhance their efficiency and sustainability further. Innovations such as smarter sensors, IoT integration, and AI-driven analytics are on the horizon, which could lead to even more optimized operations in manufacturing environments.

Moreover, as industries increasingly prioritize sustainability, the demand for vacuum roll systems is expected to grow. Companies that invest in these technologies today will likely be at the forefront of tomorrow's eco-friendly manufacturing landscape.

Conclusion

Vacuum roll systems represent a pivotal advancement in sustainable manufacturing practices. Their ability to minimize energy consumption, reduce waste, conserve resources, and enhance recyclability positions them as a vital component in the quest for eco-friendly production solutions. As industries continue to evolve, embracing vacuum technology not only makes good environmental sense but also translates into substantial economic gains.

In a world where sustainability is increasingly becoming a priority, vacuum roll systems stand out as a practical solution that meets both environmental and economic objectives. As we look to the future, investing in such technologies will not only benefit individual companies but also contribute to a more sustainable industrial landscape as a whole.

FAQs

1. What industries benefit from vacuum roll systems?

Vacuum roll systems are utilized in various industries, including packaging, textiles, automotive, and food processing, due to their versatility and efficiency in handling materials.

2. How do vacuum roll systems reduce energy consumption?

These systems consume less energy by minimizing friction and mechanical wear, employing variable speed drives, and ensuring smoother operations, leading to lower overall energy costs.

3. Can vacuum roll systems handle delicate materials?

Yes, vacuum roll systems are particularly effective in transporting delicate materials as they securely hold items in place, reducing the risk of damage during transit.

4. How do vacuum systems contribute to waste reduction?

By ensuring precise handling and minimizing product damage during transit, vacuum systems help reduce material waste and decrease the need for additional packaging.

5. Are vacuum roll systems cost-effective in the long term?

Absolutely. While the initial investment might be significant, the long-term savings from reduced energy consumption and waste make vacuum roll systems a cost-effective choice for sustainable manufacturing.

Previous Article

Previous Article

Latest News