Gear Up for Success: Ropeless Automatic Tail Threading System Insights

Published on:

2025-05-10 10:00

Gear Up for Success: Ropeless Automatic Tail Threading System Insights

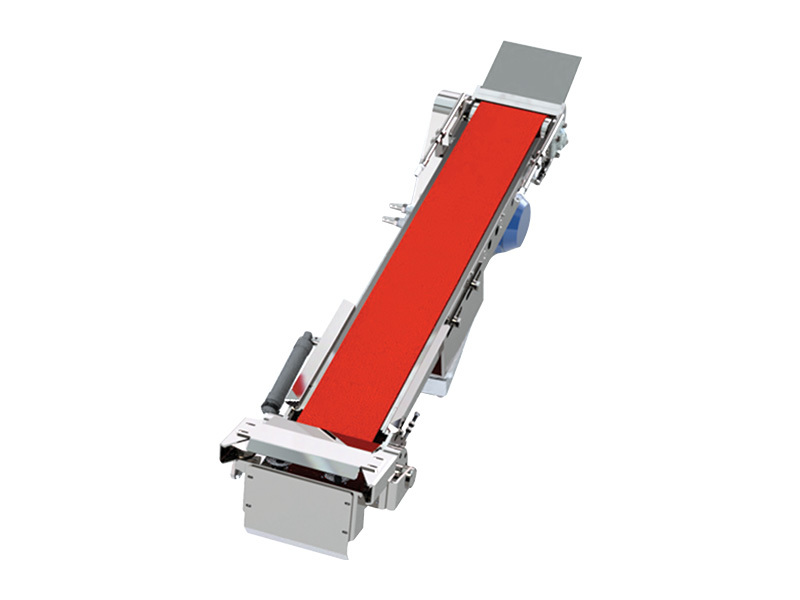

Manufacturing processes are continually evolving, and with that evolution comes the need for innovative solutions that enhance efficiency and productivity. One such innovation is the **Ropeless Automatic Tail Threading System**. This advanced technology is designed to simplify and expedite the threading process in various manufacturing settings. In this article, we will delve into the mechanics, advantages, applications, and future of the Ropeless Automatic Tail Threading System, providing insights that can help your organization gear up for success.

Understanding the Ropeless Automatic Tail Threading System

The Ropeless Automatic Tail Threading System is a groundbreaking technology that eliminates the need for traditional threading methods, which often rely on cumbersome ropes or manual intervention. This system utilizes automated processes to ensure that threading is done precisely and efficiently, reducing the chances of errors and increasing overall productivity.

How the Ropeless System Works

At its core, the Ropeless Automatic Tail Threading System operates through a combination of sensors, motors, and software algorithms. These components work together to detect the position of the fabric or material being processed. Once detected, the system automatically engages the threading mechanism, pulling the thread through the necessary components without the need for ropes or manual assistance.

Key Components of the System

1. **Sensors**: Detect the material’s position and trigger the threading process.

2. **Motors**: Control the movement of the threading mechanism with precision.

3. **Control Software**: Manages the entire threading operation, ensuring smooth execution.

4. **Threading Mechanism**: The core unit that performs the actual threading.

This combination of technology allows for a highly efficient and reliable threading process that can adapt to different materials and production speeds.

Advantages of the Ropeless Automatic Tail Threading System

Implementing the Ropeless Automatic Tail Threading System comes with numerous benefits that can significantly impact your manufacturing outcomes.

Increased Efficiency

One of the primary advantages of this system is its ability to increase operational efficiency. Traditional threading methods can be time-consuming and prone to errors, leading to delays in production. The Ropeless Automatic Tail Threading System streamlines this process, allowing for faster turnaround times and higher output rates.

Reduced Labor Costs

With automation taking over the threading process, businesses can reduce their reliance on manual labor for these tasks. This not only cuts labor costs but also allows human resources to focus on more complex and strategic tasks that require critical thinking and creativity.

Minimized Downtime

Downtime can be a significant issue in manufacturing, often resulting from mechanical failures or threading complications. The Ropeless Automatic Tail Threading System is designed to minimize these occurrences through its reliable and automated processes. This reliability leads to less downtime and more consistent production schedules.

Enhanced Precision and Quality

The automated nature of the Ropeless Automatic Tail Threading System provides enhanced precision in threading. This accurate threading reduces fabric waste and improves the overall quality of the finished products, leading to greater customer satisfaction and fewer returns.

Applications of the Ropeless Automatic Tail Threading System

The versatility of the Ropeless Automatic Tail Threading System makes it suitable for various industries and applications.

Textile Industry

In the textile industry, this system is particularly valuable for operations that involve intricate stitching or multiple layers of fabric. The efficiency and precision of the Ropeless Automatic Tail Threading System significantly enhance the production of garments, upholstery, and other fabric-based products.

Automotive Manufacturing

Automotive manufacturers can also benefit from this technology, especially in processes that involve sewing or stitching components of vehicles. The Ropeless System ensures that these processes are executed flawlessly, contributing to the overall quality and safety of the vehicles produced.

Consumer Goods Production

From handbags to sports equipment, the consumer goods industry can leverage the efficiency of the Ropeless Automatic Tail Threading System. The ability to produce high-quality items quickly and with minimal waste is a game-changer in this competitive market.

Implementing the Ropeless Automatic Tail Threading System

To successfully integrate the Ropeless Automatic Tail Threading System into your operations, several steps should be followed.

Assessment of Current Processes

Before implementation, it’s crucial to assess your current manufacturing processes. Identify the inefficiencies and challenges you face, and determine how the Ropeless Automatic Tail Threading System can address these issues.

Choosing the Right System

Not all Ropeless Automatic Tail Threading Systems are created equal. Consider the specific needs of your production environment and select a system that aligns with your operational goals.

Training and Onboarding

Once the system is selected, provide comprehensive training for your team. Understanding how to operate and maintain the system is essential for maximizing its potential and ensuring smooth integration.

Continuous Monitoring and Optimization

After implementation, it’s important to continuously monitor the system’s performance. Gather data on its efficiency, accuracy, and overall impact on production. Use this data to optimize processes and make adjustments as necessary.

Future Trends in Threading Systems

As technology continues to advance, we can expect to see even more innovations in threading systems, including:

AI and Machine Learning Integration

Future systems may integrate artificial intelligence and machine learning to further enhance their adaptability and efficiency. By analyzing data in real-time, these systems can predict potential issues and adjust operations for optimal performance.

Increased Customization

Manufacturers may also look for more customizable options in threading systems to cater to specific needs and preferences. This increased flexibility will enable businesses to tailor their operations more closely to their unique requirements.

FAQs about the Ropeless Automatic Tail Threading System

1. What is the primary benefit of the Ropeless Automatic Tail Threading System?

The primary benefit is increased efficiency in the threading process, reducing production time and labor costs.

2. Can the Ropeless Automatic Tail Threading System be used in different industries?

Yes, it is versatile and can be applied in various sectors, including textiles, automotive manufacturing, and consumer goods.

3. How does the system enhance product quality?

The system provides precise threading, minimizing errors and fabric waste, leading to higher quality finished products.

4. Is training necessary for implementing the system?

Yes, comprehensive training is essential for maximizing the system's efficiency and ensuring that team members understand its operation.

5. What future advancements can be expected in threading technology?

Future advancements may include AI integration for predictive maintenance and increased customization options for specific manufacturing needs.

Conclusion

The **Ropeless Automatic Tail Threading System** stands as a testament to the advancements in manufacturing technology, offering a multitude of benefits that can drive your operations toward greater efficiency and productivity. By understanding its mechanics, advantages, and applications, businesses can make informed decisions about integrating this innovative system into their production processes. As we gear up for a future filled with technological advancements, embracing solutions like the Ropeless Automatic Tail Threading System will undoubtedly be a step toward achieving manufacturing excellence.

Latest News