Revolutionizing Manufacturing: The Benefits of Ropeless Automatic Tail Threading Systems

Published on:

2025-05-15 10:00

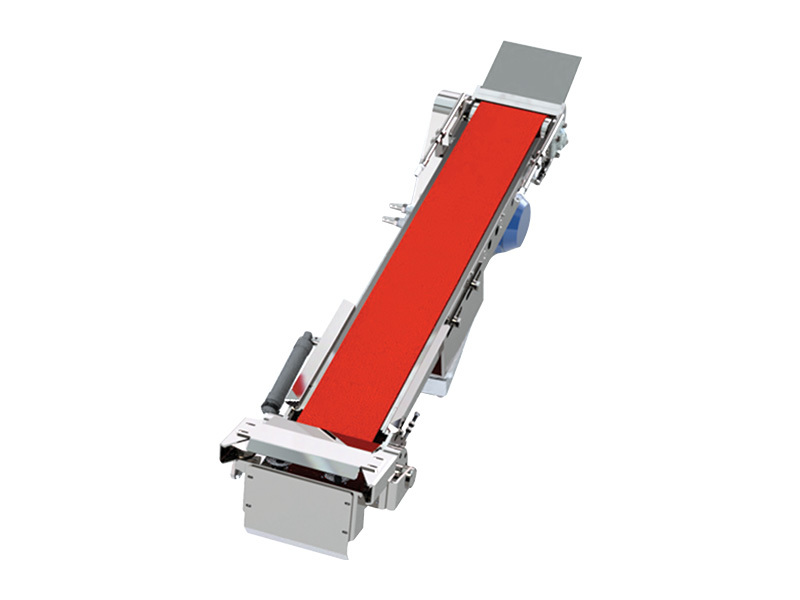

In the realm of manufacturing, efficiency and precision are paramount. One of the latest advancements in this field is the ropeless automatic tail threading system. This cutting-edge technology represents a significant leap forward in how threading operations are performed, providing numerous benefits for manufacturers seeking to streamline their processes.

Traditional threading methods often require manual intervention, which can lead to inconsistencies and increased labor costs. Ropeless automatic tail threading systems eliminate the need for manual threading by utilizing advanced mechanical designs and automation technology. This system operates without the use of a rope, allowing for a more straightforward and efficient threading process.

One of the most compelling advantages of ropeless automatic tail threading systems is the reduction in machine downtime. In conventional threading systems, the process can be time-consuming, particularly if a threading failure occurs. With an automatic system, threading can be completed quickly, allowing machines to remain operational for longer periods. This not only enhances productivity but also minimizes the risk of delays in production schedules.

Moreover, the accuracy of threading is significantly improved with ropeless automatic systems. These systems are designed to ensure that each thread is consistent and precise, which is crucial for maintaining product quality. In industries where precision is critical, such as aerospace and automotive manufacturing, the reliability of threading processes can make a substantial difference in the overall quality of the finished product.

In addition to efficiency and precision, ropeless automatic tail threading systems are also designed with safety in mind. By minimizing the need for manual handling and reducing the risk of threading-related accidents, these systems create a safer working environment for operators. This focus on safety is essential for companies looking to enhance their workplace safety standards while optimizing their manufacturing processes.

Furthermore, the integration of ropeless automatic tail threading systems can lead to substantial cost savings over time. While the initial investment may be higher than traditional systems, the long-term benefits, including increased efficiency, reduced labor costs, and improved product quality, can outweigh the upfront expenses. As manufacturers continue to seek ways to reduce costs and increase profitability, adopting such advanced technologies becomes increasingly appealing.

In conclusion, ropeless automatic tail threading systems represent a transformative solution for the manufacturing industry. By enhancing efficiency, improving accuracy, and promoting safety, these systems are set to revolutionize the way threading operations are conducted. For manufacturers looking to stay competitive in a rapidly evolving market, investing in this technology could be a game-changer. Embrace the future of manufacturing and explore the potential of ropeless automatic tail threading systems today.

Traditional threading methods often require manual intervention, which can lead to inconsistencies and increased labor costs. Ropeless automatic tail threading systems eliminate the need for manual threading by utilizing advanced mechanical designs and automation technology. This system operates without the use of a rope, allowing for a more straightforward and efficient threading process.

One of the most compelling advantages of ropeless automatic tail threading systems is the reduction in machine downtime. In conventional threading systems, the process can be time-consuming, particularly if a threading failure occurs. With an automatic system, threading can be completed quickly, allowing machines to remain operational for longer periods. This not only enhances productivity but also minimizes the risk of delays in production schedules.

Moreover, the accuracy of threading is significantly improved with ropeless automatic systems. These systems are designed to ensure that each thread is consistent and precise, which is crucial for maintaining product quality. In industries where precision is critical, such as aerospace and automotive manufacturing, the reliability of threading processes can make a substantial difference in the overall quality of the finished product.

In addition to efficiency and precision, ropeless automatic tail threading systems are also designed with safety in mind. By minimizing the need for manual handling and reducing the risk of threading-related accidents, these systems create a safer working environment for operators. This focus on safety is essential for companies looking to enhance their workplace safety standards while optimizing their manufacturing processes.

Furthermore, the integration of ropeless automatic tail threading systems can lead to substantial cost savings over time. While the initial investment may be higher than traditional systems, the long-term benefits, including increased efficiency, reduced labor costs, and improved product quality, can outweigh the upfront expenses. As manufacturers continue to seek ways to reduce costs and increase profitability, adopting such advanced technologies becomes increasingly appealing.

In conclusion, ropeless automatic tail threading systems represent a transformative solution for the manufacturing industry. By enhancing efficiency, improving accuracy, and promoting safety, these systems are set to revolutionize the way threading operations are conducted. For manufacturers looking to stay competitive in a rapidly evolving market, investing in this technology could be a game-changer. Embrace the future of manufacturing and explore the potential of ropeless automatic tail threading systems today.

Latest News