Optimizing Efficiency in Papermaking: The Role of Vacuum Roller Cleaning Systems

Published on:

2025-05-25 10:20

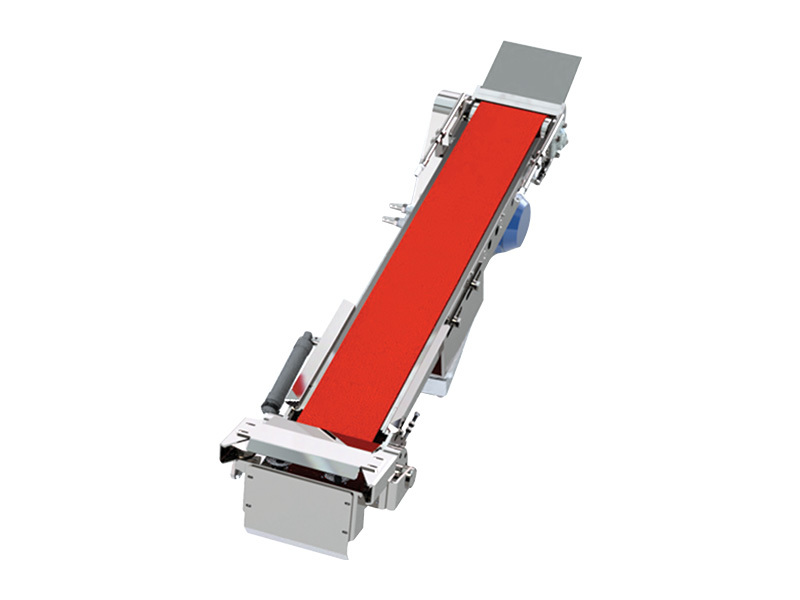

Papermaking is a complex process that involves various stages, from pulping to finishing. Among the critical components of this process is the vacuum roller, which plays a vital role in dewatering the paper sheet. However, the efficiency of these rollers can be significantly hampered by the accumulation of fibers, debris, and other contaminants. This is where vacuum roller cleaning systems come into play.

A vacuum roller cleaning system is designed to maintain the cleanliness of the roller surface, ensuring optimal performance. These systems utilize high-efficiency suction mechanisms to remove excess materials that cling to the roller during production. By doing so, they help to prevent the build-up of deposits that can lead to operational inefficiencies, such as reduced water removal rates and impaired paper quality.

The implementation of a vacuum roller cleaning system not only enhances the longevity and performance of the papermaking equipment but also contributes to overall operational efficiency. Regular cleaning ensures that the rollers maintain their designed functionality, reducing the risk of unexpected breakdowns and minimizing downtime. This is particularly crucial in a sector where any halts in production can result in significant financial losses.

Moreover, the cleaning process facilitated by these systems is highly efficient and requires minimal manual labor compared to traditional cleaning methods. This automation leads to better allocation of human resources, allowing staff to focus on more critical aspects of the production process while the cleaning system operates seamlessly in the background.

Additionally, using a vacuum roller cleaning system can positively influence the environmental footprint of a papermaking facility. By ensuring that rollers are consistently clean, the system helps to optimize water usage and energy consumption, essential factors in sustainable manufacturing practices. This aspect not only supports corporate responsibility initiatives but can also enhance brand reputation among environmentally conscious consumers.

In summary, integrating a vacuum roller cleaning system into the papermaking process is a strategic move that can lead to improved efficiency, reduced maintenance costs, and enhanced sustainability. As manufacturers seek to stay competitive in a demanding market, investing in such technologies can provide a significant edge, ensuring that production remains uninterrupted and quality standards are consistently met. Understanding the benefits of these systems is crucial for any papermaking facility aiming to enhance its operations and output quality.

A vacuum roller cleaning system is designed to maintain the cleanliness of the roller surface, ensuring optimal performance. These systems utilize high-efficiency suction mechanisms to remove excess materials that cling to the roller during production. By doing so, they help to prevent the build-up of deposits that can lead to operational inefficiencies, such as reduced water removal rates and impaired paper quality.

The implementation of a vacuum roller cleaning system not only enhances the longevity and performance of the papermaking equipment but also contributes to overall operational efficiency. Regular cleaning ensures that the rollers maintain their designed functionality, reducing the risk of unexpected breakdowns and minimizing downtime. This is particularly crucial in a sector where any halts in production can result in significant financial losses.

Moreover, the cleaning process facilitated by these systems is highly efficient and requires minimal manual labor compared to traditional cleaning methods. This automation leads to better allocation of human resources, allowing staff to focus on more critical aspects of the production process while the cleaning system operates seamlessly in the background.

Additionally, using a vacuum roller cleaning system can positively influence the environmental footprint of a papermaking facility. By ensuring that rollers are consistently clean, the system helps to optimize water usage and energy consumption, essential factors in sustainable manufacturing practices. This aspect not only supports corporate responsibility initiatives but can also enhance brand reputation among environmentally conscious consumers.

In summary, integrating a vacuum roller cleaning system into the papermaking process is a strategic move that can lead to improved efficiency, reduced maintenance costs, and enhanced sustainability. As manufacturers seek to stay competitive in a demanding market, investing in such technologies can provide a significant edge, ensuring that production remains uninterrupted and quality standards are consistently met. Understanding the benefits of these systems is crucial for any papermaking facility aiming to enhance its operations and output quality.

Latest News