Maximizing Efficiency with Vacuum Roller Cleaning Systems in Papermaking Equipment

Published on:

2025-07-04 10:20

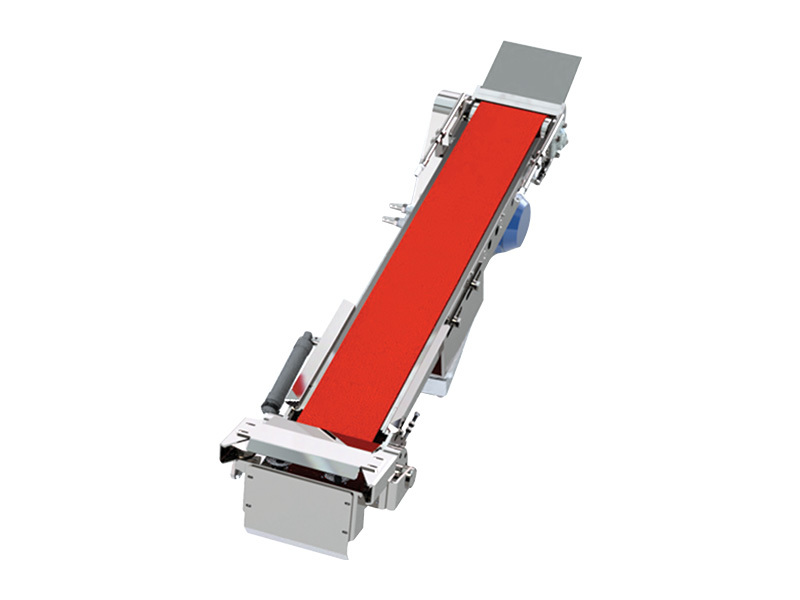

In the manufacturing sector, particularly in the papermaking industry, maintaining clean and efficient equipment is paramount for operational success. One critical component that plays a significant role in this regard is the vacuum roller cleaning system. This system is designed to enhance the performance of papermaking equipment by ensuring that rollers are free from debris, excess fiber, and other contaminants that can hinder production efficiency.

The vacuum roller cleaning system operates using a combination of suction and mechanical action to remove buildup from the roller surfaces. This is crucial in the papermaking process, where even minor contaminants can lead to quality issues in the final product. By implementing this cleaning system, manufacturers can notice a marked improvement in production quality and consistency.

One key aspect of the vacuum roller cleaning system is its ability to operate continuously without major interruptions to the production process. Traditional cleaning methods often require downtime, which can significantly affect throughput. In contrast, a well-designed vacuum cleaning system can effectively remove contaminants while the equipment is in operation, thus minimizing production delays and increasing overall efficiency.

Moreover, investing in an effective vacuum roller cleaning system can lead to reduced maintenance costs in the long term. Regularly cleaning rollers not only prevents equipment malfunction but also extends the lifespan of critical components. This preventative maintenance approach is essential for manufacturers aiming to reduce operational costs while maintaining high production standards.

From an environmental perspective, vacuum roller cleaning systems can also contribute to sustainability efforts within the papermaking industry. By ensuring that less waste is produced due to equipment inefficiencies, manufacturers can reduce their overall environmental footprint. Furthermore, cleaner equipment often results in less energy consumption during operations, making it a win-win situation for both the business and the environment.

In conclusion, integrating a vacuum roller cleaning system into papermaking equipment is a strategic move for any manufacturer looking to enhance efficiency and product quality. As the industry continues to evolve, investing in advanced cleaning technologies will be vital for staying competitive. Emphasizing maintenance, efficiency, and sustainability, vacuum roller cleaning systems represent a critical aspect of modern papermaking equipment management. Manufacturers are encouraged to assess their current cleaning procedures and consider upgrades to facilitate smoother operations and improved output quality.

The vacuum roller cleaning system operates using a combination of suction and mechanical action to remove buildup from the roller surfaces. This is crucial in the papermaking process, where even minor contaminants can lead to quality issues in the final product. By implementing this cleaning system, manufacturers can notice a marked improvement in production quality and consistency.

One key aspect of the vacuum roller cleaning system is its ability to operate continuously without major interruptions to the production process. Traditional cleaning methods often require downtime, which can significantly affect throughput. In contrast, a well-designed vacuum cleaning system can effectively remove contaminants while the equipment is in operation, thus minimizing production delays and increasing overall efficiency.

Moreover, investing in an effective vacuum roller cleaning system can lead to reduced maintenance costs in the long term. Regularly cleaning rollers not only prevents equipment malfunction but also extends the lifespan of critical components. This preventative maintenance approach is essential for manufacturers aiming to reduce operational costs while maintaining high production standards.

From an environmental perspective, vacuum roller cleaning systems can also contribute to sustainability efforts within the papermaking industry. By ensuring that less waste is produced due to equipment inefficiencies, manufacturers can reduce their overall environmental footprint. Furthermore, cleaner equipment often results in less energy consumption during operations, making it a win-win situation for both the business and the environment.

In conclusion, integrating a vacuum roller cleaning system into papermaking equipment is a strategic move for any manufacturer looking to enhance efficiency and product quality. As the industry continues to evolve, investing in advanced cleaning technologies will be vital for staying competitive. Emphasizing maintenance, efficiency, and sustainability, vacuum roller cleaning systems represent a critical aspect of modern papermaking equipment management. Manufacturers are encouraged to assess their current cleaning procedures and consider upgrades to facilitate smoother operations and improved output quality.

Previous Article

Previous Article

Latest News