Efficiency at its Best: Maximizing Results with Automatic Tail Cutters

Published on:

2025-07-09 10:00

Efficiency at its Best: Maximizing Results with Automatic Tail Cutters

Table of Contents

- 1. Introduction to Automatic Tail Cutters

- 2. What Are Automatic Tail Cutters?

- 3. Benefits of Using Automatic Tail Cutters

- 4. Types of Automatic Tail Cutters

- 5. Applications of Automatic Tail Cutters in Industry

- 6. Key Features to Look for in Automatic Tail Cutters

- 7. Maintenance Tips for Optimal Performance

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Automatic Tail Cutters

In the ever-evolving landscape of industrial technology, efficiency and productivity remain paramount. **Automatic tail cutters** have emerged as essential tools that significantly enhance manufacturing processes. These advanced devices are designed to streamline operations, reduce waste, and maximize output. Understanding the workings and advantages of automatic tail cutters can help businesses achieve remarkable results.

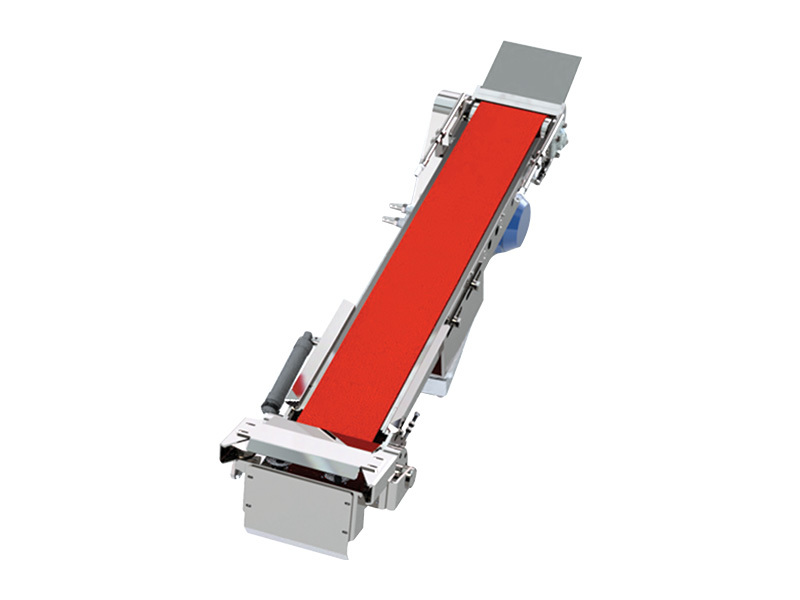

2. What Are Automatic Tail Cutters?

Automatic tail cutters are specialized tools used in various industrial applications to trim excess material from the ends of workpieces. They employ advanced technology to ensure precise cuts, thereby improving the overall quality of the final product. Unlike manual cutting methods, automatic tail cutters offer enhanced speed, accuracy, and consistency, making them indispensable in modern manufacturing.

3. Benefits of Using Automatic Tail Cutters

The incorporation of automatic tail cutters into manufacturing processes offers numerous benefits that contribute to operational efficiency:

3.1 Increased Production Speed

Automatic tail cutters are designed for rapid operation, allowing businesses to produce more in less time. This acceleration in production speed directly translates to increased output and profitability.

3.2 Improved Precision

With advanced cutting technology, these tools deliver precise cuts that minimize errors. This precision is crucial in maintaining product quality and ensuring customer satisfaction.

3.3 Waste Reduction

By efficiently trimming excess material, automatic tail cutters help reduce waste. This not only lowers production costs but also supports sustainability efforts within manufacturing processes.

3.4 Enhanced Worker Safety

Automating the cutting process minimizes the risks associated with manual cutting methods. Workers are less exposed to dangerous tools, leading to a safer workplace environment.

3.5 Versatility in Applications

Automatic tail cutters are adaptable to various materials and cutting requirements, making them suitable for a wide range of industries, including automotive, aerospace, and electronics.

4. Types of Automatic Tail Cutters

Understanding the different types of automatic tail cutters available can help businesses choose the right tool for their specific needs. Here’s a closer look at the most common types:

4.1 Rotary Tail Cutters

Rotary tail cutters use a rotating blade to make quick and efficient cuts. They are ideal for cylindrical materials and are commonly used in industries where high-speed processing is required.

4.2 Saw Blade Tail Cutters

Saw blade tail cutters utilize serrated blades to cut through various materials, including metal and plastic. Their robust design makes them suitable for heavy-duty applications, ensuring clean and accurate cuts.

4.3 Shear Tail Cutters

Shear tail cutters use a scissor-like action to slice through materials. They are particularly effective for thin materials and offer a high level of control, making them ideal for delicate operations.

5. Applications of Automatic Tail Cutters in Industry

Automatic tail cutters find applications across various industries due to their efficiency and versatility. Here are some notable applications:

5.1 Automotive Manufacturing

In the automotive industry, automatic tail cutters are used to trim excess material from components, ensuring precision and consistency in production.

5.2 Aerospace Production

Aerospace manufacturers rely on these tools for high-precision cuts in critical components, where accuracy and quality are non-negotiable.

5.3 Electronics Assembly

In electronics assembly, automatic tail cutters are utilized to trim leads and components, enhancing the efficiency of the manufacturing process.

5.4 Metal Fabrication

Metal fabrication shops use automatic tail cutters to streamline their cutting processes, improving turnaround times and reducing labor costs.

6. Key Features to Look for in Automatic Tail Cutters

Choosing the right automatic tail cutter involves understanding the essential features that enhance performance and reliability:

6.1 Cutting Speed and Efficiency

Look for tools that offer adjustable cutting speeds to accommodate various materials and thicknesses, maximizing efficiency across different applications.

6.2 Precision Control

Ensure that the automatic tail cutter provides precise control mechanisms, such as programmable settings, to maintain high-quality cuts consistently.

6.3 Safety Features

Safety should be a priority. Choose automatic tail cutters equipped with safety guards and emergency stop functions to protect operators.

6.4 Durability and Maintenance

Select tools made from high-quality materials that can withstand the rigors of industrial use. Additionally, consider models that are easy to maintain.

6.5 Compatibility

Ensure that the tail cutter is compatible with your existing machinery and materials for seamless integration into your production line.

7. Maintenance Tips for Optimal Performance

Proper maintenance is crucial for the longevity and performance of automatic tail cutters. Here are some essential tips:

7.1 Regular Cleaning

Keep the cutter clean and free from debris to prevent clogs and ensure smooth operation.

7.2 Routine Inspections

Conduct routine inspections to identify wear and tear on blades and components, replacing them as necessary to maintain cutting efficiency.

7.3 Lubrication

Properly lubricate moving parts to reduce friction and extend the life of the equipment.

7.4 Follow Manufacturer Guidelines

Always adhere to the manufacturer’s maintenance guidelines to ensure optimal performance and avoid voiding warranties.

8. Frequently Asked Questions

8.1 What materials can automatic tail cutters handle?

Automatic tail cutters can handle a variety of materials, including metals, plastics, and composites, depending on the design and blade type.

8.2 How do I choose the right automatic tail cutter for my needs?

Consider factors such as the material type, thickness, desired cutting speed, and the specific application when selecting an automatic tail cutter.

8.3 What is the average lifespan of an automatic tail cutter?

The lifespan of an automatic tail cutter varies based on usage, maintenance, and quality, but with proper care, they can last several years.

8.4 Can automatic tail cutters be integrated with existing machinery?

Yes, most automatic tail cutters are designed for compatibility with existing machinery, making integration relatively straightforward.

8.5 What safety precautions should I take when using automatic tail cutters?

Always follow safety guidelines provided by the manufacturer, use appropriate personal protective equipment, and ensure that all safety features are functional before operating the cutter.

9. Conclusion

Automatic tail cutters represent a significant advancement in industrial technology, providing unparalleled efficiency and precision in manufacturing processes. By understanding their benefits, types, and applications, businesses can leverage these tools to maximize results and enhance productivity. Investing in high-quality automatic tail cutters not only streamlines operations but also fosters a safer and more sustainable manufacturing environment. Embrace the future of industrial cutting with automatic tail cutters and elevate your production capabilities to new heights.

Previous Article

Previous Article

Latest News