Understanding the Benefits of Automatic Tail Cutters for Dryer Sections in Industrial Equipment

Published on:

2025-10-30 09:20

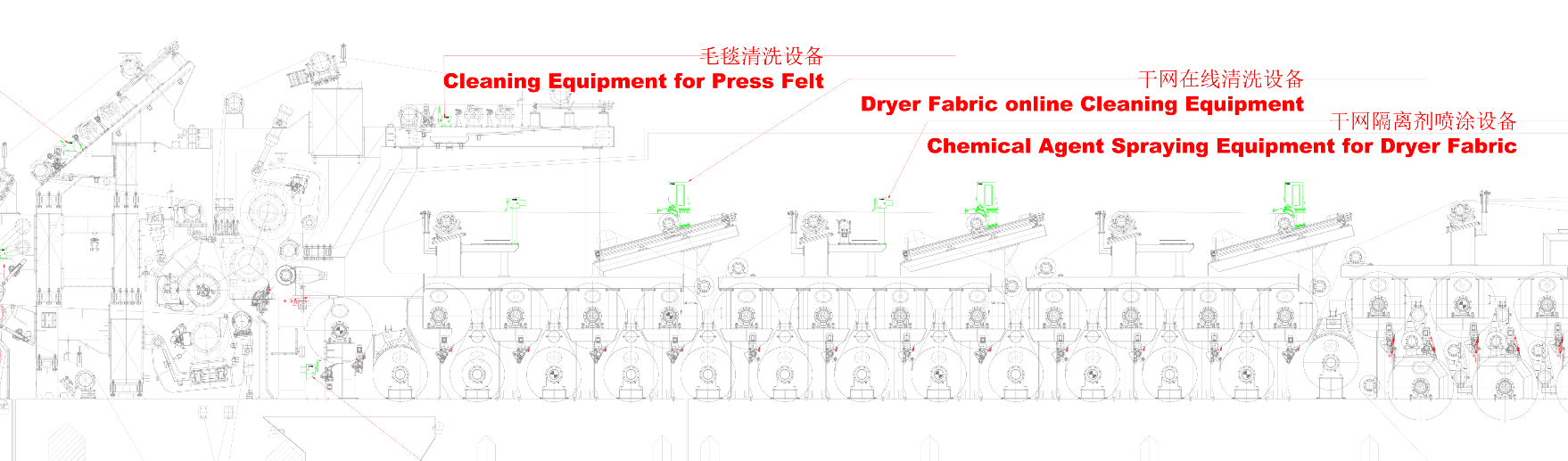

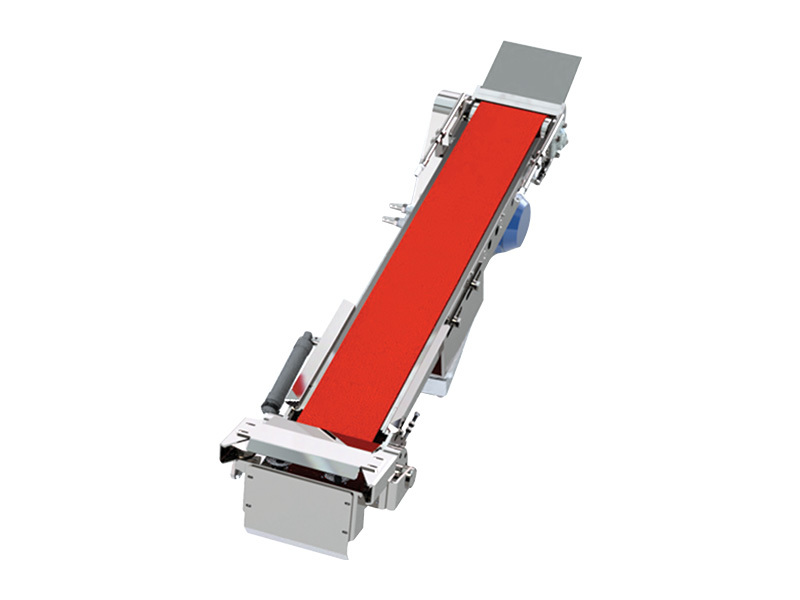

In the world of industrial equipment and components, particularly in the realm of tooling and fixtures, the automatic tail cutter for dryer sections plays a crucial role in optimizing performance and quality. This innovative tool is designed to enhance the efficiency of the drying process by ensuring that the tails, or excess materials, are cut away automatically, reducing waste and improving the overall output of the machinery.

The primary function of an automatic tail cutter is to manage the composite materials processed in the dryer section. As materials pass through the dryer, they often produce tails—excess ends that can lead to inefficiencies if not managed properly. By automating this cutting process, operators can ensure a more consistent and cleaner cut, which is essential for maintaining the quality of the final product. This not only minimizes waste but also enhances the overall production rate, allowing for smoother operations.

One of the significant advantages of using an automatic tail cutter in dryer sections is its ability to maintain precise cutting without manual intervention. This precision is vital, especially in industries where the quality of the material is paramount. Manual cutting can lead to variations in the cut quality, whereas automated systems provide uniformity and reliability, ensuring that each piece meets the required specifications.

Moreover, integrating an automatic tail cutter into the dryer section can significantly reduce labor costs. With less need for manual labor to monitor and manage the cutting process, companies can allocate their workforce more efficiently, directing human resources toward more strategic tasks. This not only helps in cost-saving but also improves productivity as workers can focus on areas of higher value within the manufacturing process.

Additionally, the implementation of automatic tail cutters enhances safety in the workplace. Automated systems are designed with safety features that reduce the risk of accidents, which can be common in manual cutting operations. By minimizing human intervention in potentially hazardous areas, companies can create a safer working environment for their employees.

In conclusion, the automatic tail cutter for dryer sections represents a significant advancement in industrial equipment technology. By providing a reliable, efficient, and safe solution to manage excess materials, these tools play a fundamental role in improving productivity and maintaining product quality in various manufacturing processes. As industries continually seek ways to enhance their operations, the adoption of such innovative tools will undoubtedly pave the way for more efficient manufacturing practices in the future. Embracing these advancements is essential for businesses looking to stay competitive in an ever-evolving market.

The primary function of an automatic tail cutter is to manage the composite materials processed in the dryer section. As materials pass through the dryer, they often produce tails—excess ends that can lead to inefficiencies if not managed properly. By automating this cutting process, operators can ensure a more consistent and cleaner cut, which is essential for maintaining the quality of the final product. This not only minimizes waste but also enhances the overall production rate, allowing for smoother operations.

One of the significant advantages of using an automatic tail cutter in dryer sections is its ability to maintain precise cutting without manual intervention. This precision is vital, especially in industries where the quality of the material is paramount. Manual cutting can lead to variations in the cut quality, whereas automated systems provide uniformity and reliability, ensuring that each piece meets the required specifications.

Moreover, integrating an automatic tail cutter into the dryer section can significantly reduce labor costs. With less need for manual labor to monitor and manage the cutting process, companies can allocate their workforce more efficiently, directing human resources toward more strategic tasks. This not only helps in cost-saving but also improves productivity as workers can focus on areas of higher value within the manufacturing process.

Additionally, the implementation of automatic tail cutters enhances safety in the workplace. Automated systems are designed with safety features that reduce the risk of accidents, which can be common in manual cutting operations. By minimizing human intervention in potentially hazardous areas, companies can create a safer working environment for their employees.

In conclusion, the automatic tail cutter for dryer sections represents a significant advancement in industrial equipment technology. By providing a reliable, efficient, and safe solution to manage excess materials, these tools play a fundamental role in improving productivity and maintaining product quality in various manufacturing processes. As industries continually seek ways to enhance their operations, the adoption of such innovative tools will undoubtedly pave the way for more efficient manufacturing practices in the future. Embracing these advancements is essential for businesses looking to stay competitive in an ever-evolving market.

Latest News