Maximizing Efficiency: The Role of Automatic Tail Cutters in Dryer Sections

Published on:

2025-11-13 09:00

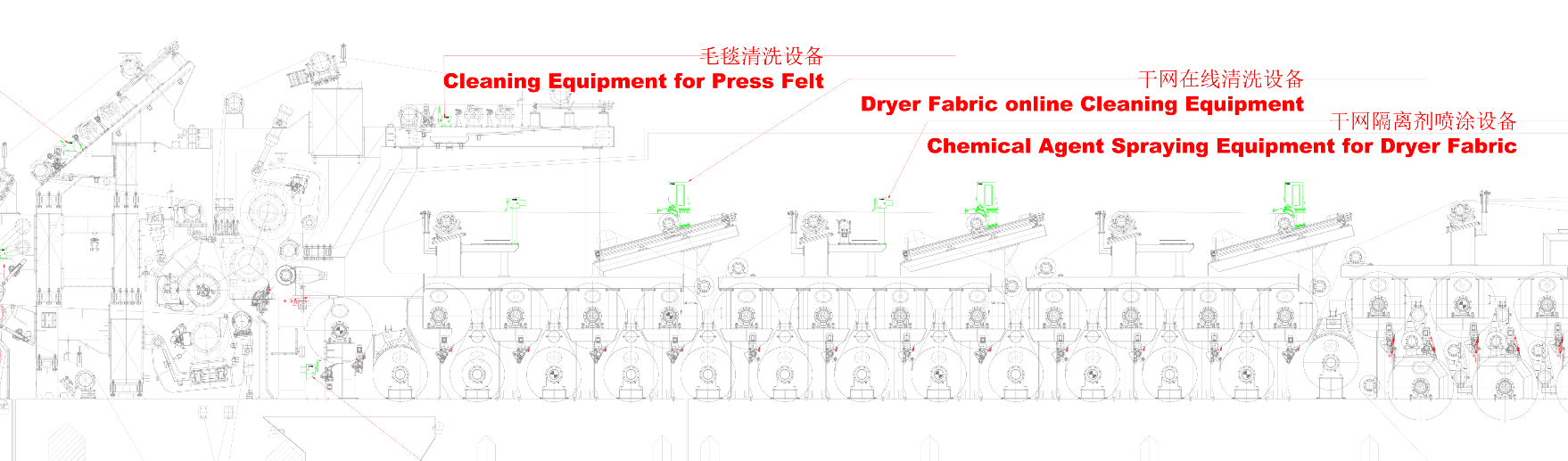

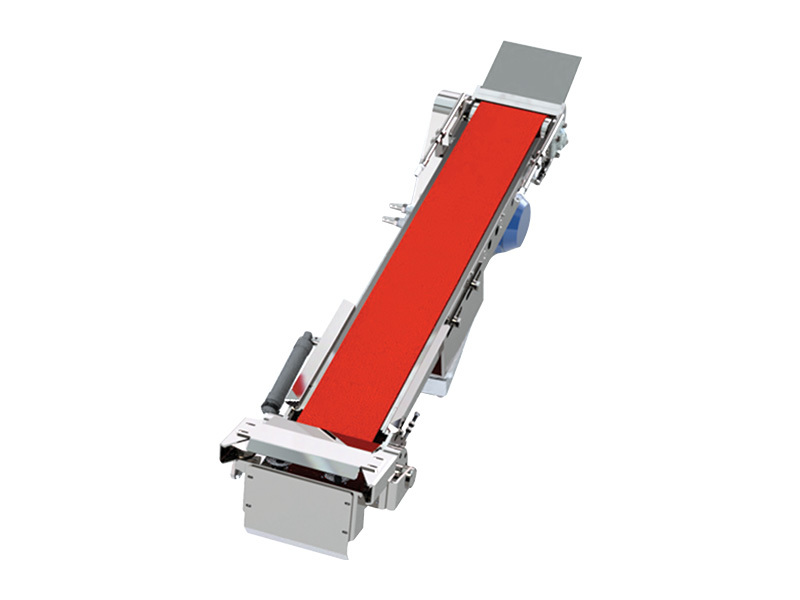

In various industrial settings, particularly in the manufacturing of paper and textiles, maintaining efficiency and product quality is paramount. One key element in achieving this is the use of automatic tail cutters in the dryer section. These innovative devices are engineered to automate the process of trimming excess material, commonly referred to as "tails," from the end of the production line. This task, often performed manually, can be time-consuming and prone to human error, making the automatic tail cutter an essential addition to modern production facilities.

The primary function of the automatic tail cutter is to enhance productivity by ensuring a clean cut of the material as it exits the dryer section. This not only reduces waste but also aids in maintaining uniformity in the final product. By employing precision cutting techniques, these machines ensure that every piece produced meets stringent quality standards, which is vital for sustaining customer satisfaction and reducing the likelihood of rework.

Additionally, automatic tail cutters are designed to integrate seamlessly into existing production lines. They can be programmed to operate at varying speeds and can handle different types of materials, making them versatile solutions for various industries. This adaptability is crucial in environments where production demands fluctuate, allowing manufacturers to remain competitive without sacrificing quality or efficiency.

Another significant benefit of automatic tail cutters is their contribution to safety. Manual cutting processes often expose operators to potential injuries from blades and machinery. By automating this function, the risks associated with manual labor are greatly minimized, creating a safer workplace for employees.

Moreover, the implementation of automatic tail cutters can lead to cost savings over time. While the initial investment in such technology may be considerable, the reduction in material waste, improvement in production speed, and enhanced safety measures contribute to overall operational efficiency. This results in a quicker return on investment and supports long-term financial sustainability.

In conclusion, the incorporation of automatic tail cutters in the dryer section represents a significant advancement in industrial equipment technology. By automating the cutting process, these devices not only improve productivity and product quality but also enhance workplace safety and operational efficiency. For professionals in the industrial sector, understanding the role and benefits of such tools is essential for staying ahead in a competitive market. As industries continue to evolve, embracing innovations like automatic tail cutters will be pivotal for sustainable growth and success.

The primary function of the automatic tail cutter is to enhance productivity by ensuring a clean cut of the material as it exits the dryer section. This not only reduces waste but also aids in maintaining uniformity in the final product. By employing precision cutting techniques, these machines ensure that every piece produced meets stringent quality standards, which is vital for sustaining customer satisfaction and reducing the likelihood of rework.

Additionally, automatic tail cutters are designed to integrate seamlessly into existing production lines. They can be programmed to operate at varying speeds and can handle different types of materials, making them versatile solutions for various industries. This adaptability is crucial in environments where production demands fluctuate, allowing manufacturers to remain competitive without sacrificing quality or efficiency.

Another significant benefit of automatic tail cutters is their contribution to safety. Manual cutting processes often expose operators to potential injuries from blades and machinery. By automating this function, the risks associated with manual labor are greatly minimized, creating a safer workplace for employees.

Moreover, the implementation of automatic tail cutters can lead to cost savings over time. While the initial investment in such technology may be considerable, the reduction in material waste, improvement in production speed, and enhanced safety measures contribute to overall operational efficiency. This results in a quicker return on investment and supports long-term financial sustainability.

In conclusion, the incorporation of automatic tail cutters in the dryer section represents a significant advancement in industrial equipment technology. By automating the cutting process, these devices not only improve productivity and product quality but also enhance workplace safety and operational efficiency. For professionals in the industrial sector, understanding the role and benefits of such tools is essential for staying ahead in a competitive market. As industries continue to evolve, embracing innovations like automatic tail cutters will be pivotal for sustainable growth and success.

Latest News