Innovative Solutions: Ropeless Automatic Tail Threading System Revolution

Published on:

2025-11-20 09:50

Innovative Solutions: Ropeless Automatic Tail Threading System Revolution

Introduction to the Ropeless Automatic Tail Threading System

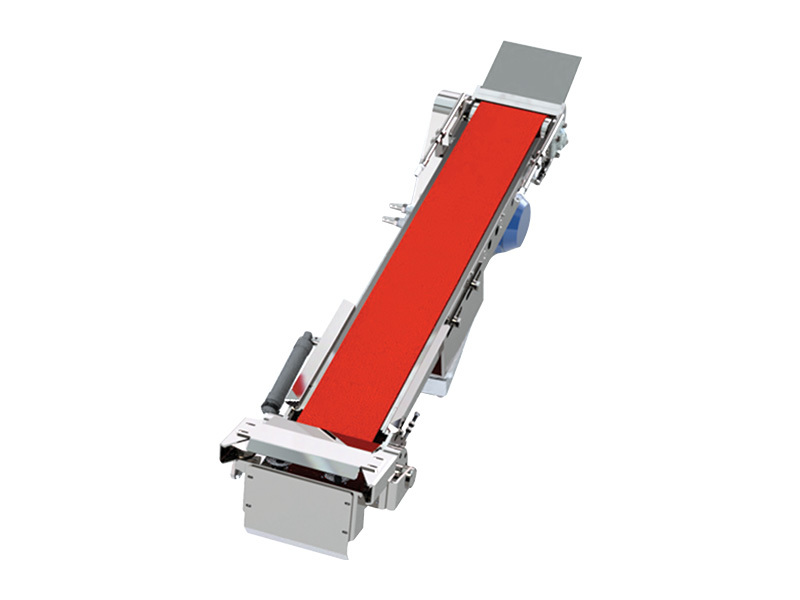

In the ever-evolving landscape of manufacturing technology, the **Ropeless Automatic Tail Threading System** emerges as a groundbreaking solution. This system enhances the efficiency of various manufacturing processes, particularly in the textile and stitching industries. By eliminating the need for traditional roping methods, this innovative approach streamlines production, reduces downtime, and ultimately delivers superior operational outcomes.

Understanding the Need for Innovation in Manufacturing

Manufacturers constantly seek ways to improve productivity and reduce costs in an increasingly competitive market. Traditional threading methods typically involve cumbersome processes that can lead to significant delays and waste of resources. The introduction of the **Ropeless Automatic Tail Threading System** addresses these challenges head-on. It offers several advantages that not only enhance efficiency but also promote sustainable practices.

The Challenges of Traditional Threading Systems

Traditional threading systems often involve multiple steps and manual intervention, which can lead to various issues:

- **Downtime**: Machine operators spend valuable time threading machines, which could be better used for production tasks.

- **Material Waste**: Incorrect threading can lead to thread breakage and wasted materials, increasing production costs.

- **Quality Assurance**: Manual processes often lead to inconsistencies in quality, resulting in defective products.

Benefits of the Ropeless Automatic Tail Threading System

The **Ropeless Automatic Tail Threading System** introduces a range of benefits that significantly outpace traditional methods:

1. **Increased Efficiency**: Automating the threading process reduces the time taken to prepare machines for operation. This increases overall productivity.

2. **Cost Reduction**: By minimizing material waste and downtime, manufacturers can achieve substantial cost savings.

3. **Improved Quality**: The precision of an automated system ensures consistent quality in the finished product.

4. **Ease of Use**: The system is designed for user-friendliness, allowing operators to focus on more critical tasks without the need for extensive training.

How the Ropeless Automatic Tail Threading System Works

The operation of the **Ropeless Automatic Tail Threading System** is a marvel of modern engineering. It employs advanced technology to facilitate a seamless threading process.

Key Components of the System

- **Automated Thread Feed**: This component ensures a consistent supply of thread to the machine, eliminating the need for manual intervention.

- **Sensors and Control Systems**: Integrated sensors monitor the threading process, providing real-time data to operators and enabling quick adjustments if necessary.

- **Safety Mechanisms**: Built-in safety features protect operators and prevent damage to machinery in case of malfunctions.

The Threading Process Explained

1. **Initialization**: The system is set up to recognize the type of thread and material being used.

2. **Thread Feed Activation**: Upon initiation, the automated thread feed begins to supply the necessary amount of thread, ensuring optimal tension.

3. **Thread Path Alignment**: Sensors guide the thread along the correct path, ensuring that it is threaded accurately without tangles or breaks.

4. **Finalization**: Once threading is complete, the system confirms the successful operation, allowing production to commence without delay.

Applications Across Industries

The versatility of the **Ropeless Automatic Tail Threading System** makes it suitable for a wide range of industries beyond textiles, including:

Textile Manufacturing

In textile mills, this innovative system drastically reduces setup times, enabling quicker transitions between production runs. It enhances the quality of stitching, resulting in superior fabric products.

Automotive Industry

Manufacturers in the automotive sector benefit from this technology by ensuring precise assembly of components that require stitching, ultimately improving the overall quality of the vehicles produced.

Furniture Production

In the furniture industry, the system allows for efficient production of upholstered goods. By streamlining the threading process, manufacturers can meet demand without compromising on quality.

Future Trends in Threading Technology

As we look toward the future, it is evident that the **Ropeless Automatic Tail Threading System** will pave the way for further innovations in threading technology. Key trends include:

Integration with Industry 4.0

The integration of the system with IoT (Internet of Things) will enable data analytics to optimize production processes further. Real-time monitoring and adjustments will lead to smarter manufacturing.

Enhanced Automation

As automation technology advances, we can expect even more sophisticated threading systems that incorporate artificial intelligence to predict and solve threading issues before they occur.

Sustainability Initiatives

With a growing focus on sustainability, future threading systems will likely prioritize eco-friendly materials and processes, further reducing waste and energy consumption.

Implementing the Ropeless Automatic Tail Threading System in Your Business

Integrating the **Ropeless Automatic Tail Threading System** into your manufacturing operations requires careful planning and execution. Here are some key steps to consider:

Assessment of Current Processes

Evaluate your existing threading methods to identify bottlenecks and inefficiencies. Understanding your current state helps in planning the transition to the new system.

Training for Staff

Invest in training programs for your workforce to ensure they are comfortable with the new technology. A well-informed team can maximize the benefits of the system.

Monitoring Performance Metrics

Once implemented, closely monitor performance metrics such as production speed, material waste, and quality outcomes. This data will help you assess the impact of the new system and make necessary adjustments.

Frequently Asked Questions (FAQs)

1. What is the Ropeless Automatic Tail Threading System?

The Ropeless Automatic Tail Threading System is an innovative technology designed to automate the threading process in manufacturing, improving efficiency and quality.

2. How does this system improve productivity?

By eliminating manual threading and reducing setup times, the system allows for faster production cycles, leading to increased productivity.

3. Which industries benefit from this technology?

Industries such as textiles, automotive, and furniture production can significantly benefit from the Ropeless Automatic Tail Threading System.

4. Is training required to operate the system?

While the system is designed to be user-friendly, training is recommended to ensure that operators can effectively use the technology.

5. What are the long-term benefits of implementing this system?

Long-term benefits include cost savings, reduced material waste, improved product quality, and enhanced operational efficiency.

Conclusion

The **Ropeless Automatic Tail Threading System** represents a significant leap forward in manufacturing technology. By addressing the inefficiencies of traditional threading methods, it provides manufacturers with a unique opportunity to enhance productivity, reduce costs, and improve product quality. As industries continue to evolve, embracing innovations like this system will be crucial for maintaining competitiveness and driving sustainable growth. Investing in such technologies not only prepares businesses for the future but also positions them as leaders in their respective fields.

Previous Article

Previous Article

Latest News