Revolutionizing Industrial Efficiency: The Future of Automatic Tail Cutters

Published on:

2025-11-06 09:50

Revolutionizing Industrial Efficiency: The Future of Automatic Tail Cutters

Table of Contents

- 1. Introduction to Automatic Tail Cutters

- 2. What Are Automatic Tail Cutters?

- 3. Benefits of Implementing Automatic Tail Cutters

- 4. Technology Behind Automatic Tail Cutters

- 5. Best Practices for Implementing Automatic Tail Cutters

- 6. Case Studies: Successful Implementations

- 7. Future Trends in Automatic Tail Cutting Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Automatic Tail Cutters

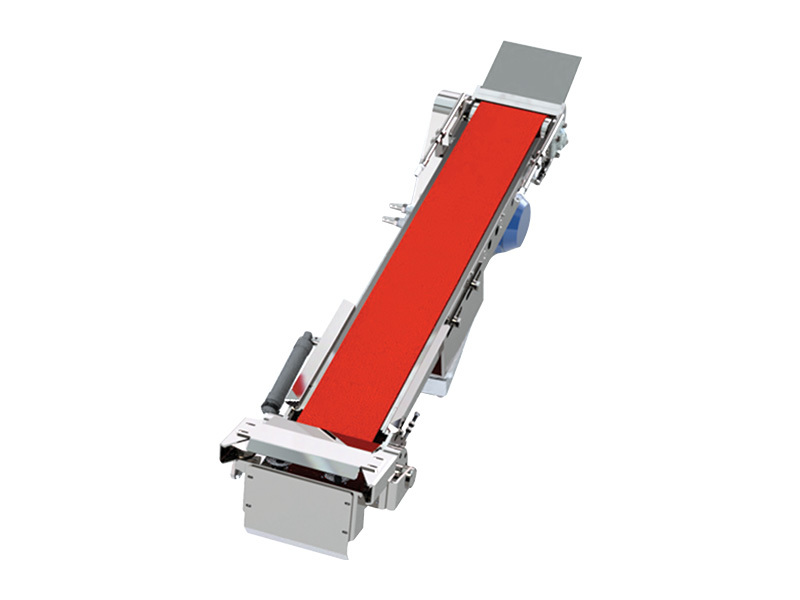

The realm of industrial equipment and components is continually evolving, with **automatic tail cutters** emerging as a groundbreaking innovation. These tools are designed to streamline manufacturing processes by automating the cutting of excess material, commonly referred to as "tails." In an environment where efficiency and precision are paramount, understanding the role of these devices is crucial for businesses aiming to enhance productivity.

2. What Are Automatic Tail Cutters?

Automatic tail cutters are advanced machines that utilize cutting-edge technology to remove surplus material from products during the manufacturing process. By implementing these systems, manufacturers can significantly reduce manual labor, enhance operational speed, and ensure quality control. Tail cutters can be integrated into various manufacturing lines, making them versatile and essential for modern industrial processes.

2.1 How Do They Work?

The operation of automatic tail cutters typically involves a combination of sensors, cutting mechanisms, and programmable logic controllers (PLCs). These components work together to detect excess material, determine the optimal cutting position, and execute precise cuts without human intervention.

3. Benefits of Implementing Automatic Tail Cutters

The integration of automatic tail cutters into manufacturing processes offers numerous advantages that can transform operations. Below, we explore these benefits in detail.

3.1 Efficiency Improvement

By automating the cutting process, manufacturers can achieve **higher throughput rates**. Automatic tail cutters can operate continuously without breaks, unlike human workers. This leads to faster production cycles and minimizes downtime, ultimately resulting in increased output.

3.2 Cost Reduction

Implementing automatic tail cutters can lead to substantial cost savings. The reduction in labor costs due to decreased reliance on manual cutting allows businesses to allocate resources more effectively. Additionally, the precision of automatic cuts reduces material waste, further contributing to cost efficiency.

3.3 Enhanced Quality

Automatic tail cutters ensure consistent quality in manufacturing. The precision of these machines eliminates human error, leading to uniform products that meet stringent quality standards. This is particularly important in industries where tolerances are critical, such as aerospace and automotive.

4. Technology Behind Automatic Tail Cutters

Understanding the technology that drives automatic tail cutters is essential for leveraging their full potential.

4.1 Mechanisms of Operation

Automatic tail cutters typically utilize **CNC (Computer Numerical Control)** technology, enabling precise control over cutting parameters. This technology allows manufacturers to program complex cutting patterns and adjust settings based on the material being processed.

4.2 Integration with Existing Systems

One of the significant advantages of automatic tail cutters is their ability to integrate seamlessly with existing manufacturing systems. These tools can be customized to work alongside other machines, enhancing the overall efficiency of production lines.

5. Best Practices for Implementing Automatic Tail Cutters

To maximize the benefits of automatic tail cutters, manufacturers should consider the following best practices during implementation:

1. **Conduct a Needs Assessment:** Understand the specific requirements of your production process to choose the right tail cutter.

2. **Invest in Training:** Ensure that operators are well-trained in the use of automatic tail cutters to maximize efficiency and safety.

3. **Regular Maintenance:** Schedule routine maintenance to keep the machinery in optimal condition, preventing unexpected breakdowns.

4. **Monitor Performance:** Utilize data analytics to track the performance of tail cutters, enabling continuous improvement.

6. Case Studies: Successful Implementations

Examining real-world examples can provide valuable insights into the impact of automatic tail cutters.

6.1 Aerospace Industry

A leading aerospace manufacturer integrated automatic tail cutters into their production line, resulting in a **30% increase in output** and a significant reduction in material waste. This case highlights the crucial role of precision in high-stakes industries.

6.2 Automotive Sector

An automotive parts producer adopted automatic tail cutters, enabling them to streamline operations. The investment paid off within a year as they noted a **25% reduction in labor costs**, showcasing the financial benefits of automation.

7. Future Trends in Automatic Tail Cutting Technology

As technology continues to evolve, so too will automatic tail cutters. Future trends may include:

- **Artificial Intelligence Integration:** AI could enable tail cutters to learn from past operations, optimizing cutting processes over time.

- **Enhanced Connectivity:** IoT (Internet of Things) capabilities may allow for remote monitoring and diagnostics, improving maintenance efficiency.

- **Sustainable Practices:** The push for sustainability will likely lead to the development of tail cutters that minimize energy consumption and waste.

8. Frequently Asked Questions

8.1 What industries benefit the most from automatic tail cutters?

Industries such as aerospace, automotive, and manufacturing of precision parts greatly benefit from automatic tail cutters due to their need for high accuracy and efficiency.

8.2 How do automatic tail cutters improve safety in the workplace?

By reducing the need for manual cutting, automatic tail cutters minimize the risk of workplace accidents associated with cutting tools.

8.3 Are automatic tail cutters customizable?

Yes, many manufacturers offer customizable options to ensure that the tail cutters meet specific production requirements.

8.4 What is the average return on investment for automatic tail cutters?

The return on investment can vary, but many companies report recouping their initial costs within one to two years through increased efficiency and reduced labor costs.

8.5 How do I choose the right automatic tail cutter for my operation?

Consider factors such as the type of material you process, production volume, and specific cutting requirements when selecting an automatic tail cutter.

9. Conclusion

Incorporating automatic tail cutters into manufacturing processes represents a significant leap towards enhanced operational efficiency. By embracing this innovative technology, businesses can not only improve productivity and reduce costs but also ensure superior quality in their products. As industries continue to evolve, staying ahead of the curve with technology like automatic tail cutters will be essential for maintaining competitiveness in a rapidly changing market. Adopting these solutions is not just a trend; it is a strategic move towards a more efficient, sustainable, and profitable future.

Latest News